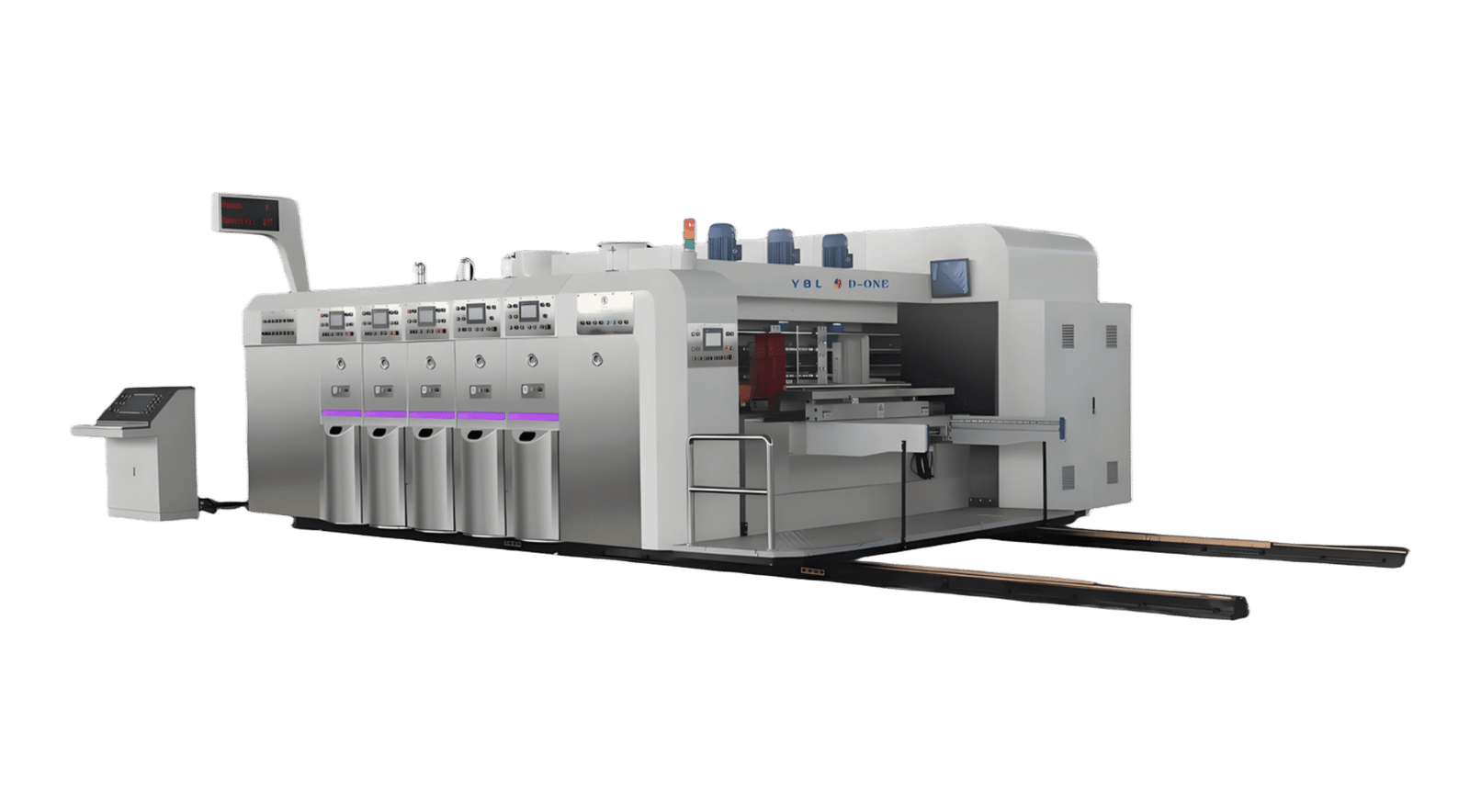

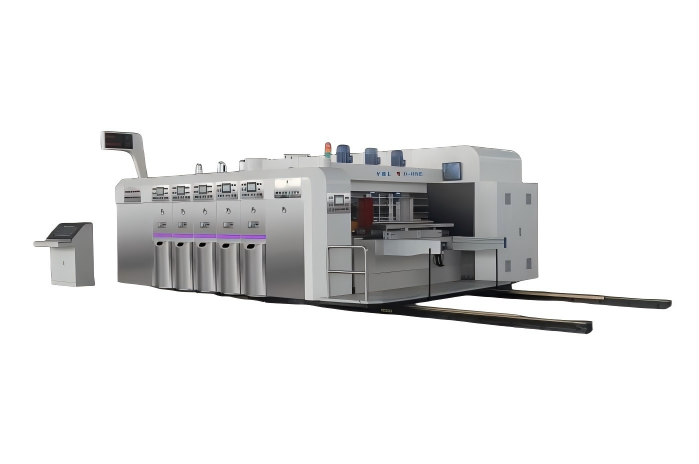

◆ 滚筒式前缘进纸机构,多轮、多点吸入式进纸,提供高摩擦、高速、平稳、精确的进纸。.

吸气量通过变频调节,气压可根据纸板尺寸进行调节,提高了薄纸板和翘曲纸板的传输稳定性和准确性。.

◆ 双辊进纸结构:一组进纸辊采用气动弹性进纸辊,不会破坏瓦楞纸板的强度。清洁刷可清除表面碎屑,高压风扇可清除纸板表面的杂质,提高印刷质量。.

◆ 左右挡板和后挡板可电动调节,前挡板间隙可手动调节。侧挡板配有气动对齐装置,可实现更精确的水平纸板定位。.

10.4 英寸彩色触摸屏可控制送纸、打印、开槽和模切部分,并具有一次性复位、订单存储、记忆定位、60、80、100 和 120 英里/小时巡航控制、红外光电计数和预设订单数量等功能。.

◆ 主机采用变频控制,启动和运行平稳,节省 30% 能源。.