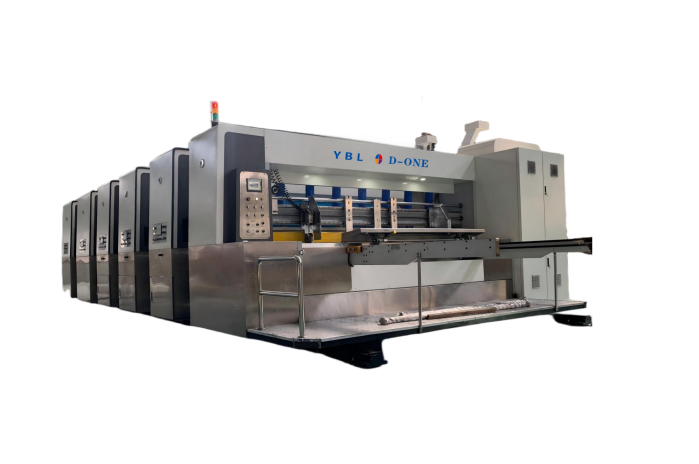

前沿进纸增加了风扇流量,在高速和低速时都能保持精确的进纸。.

◆ 分段式气流和纸板尺寸调整。.

前挡板定位可减少送纸误差,提高送纸、打印和模切精度。.

◆ 左右侧挡板由电机驱动,可左右移动,并具有纸板对齐功能。.

后纸板支架可电动前后移动。.

前挡板间隙调节为手动同步调节。.

提供连续进纸和跳过进纸功能(可根据需要选择连续进纸或跳过进纸)。.

◆ 上下送纸辊:

◆ 上滚轮:钢管外覆耐磨丁腈橡胶,可实现平衡运行。.

◆ 下辊:进纸辊表面有硬铬电镀压花。.

进纸压力辊间隙调节采用自锁机构,调节范围为 0-11mm。.

◆ 压辊由滚动式十字联轴器驱动,可减少磨损,确保传动更加平衡。◆ 机器可以分离和组合,并配有警报器,在操作过程中持续鸣响,确保操作人员的安全。.

◆ 移动轴配有摩擦离合器,以防止因操作不当而损坏机器。.

◆ 主机电机在启动时配有保护装置(如果机器未锁定,主机将无法启动)。.

◆ 进纸装置通过电气方式自动归零。.

◆ 自动归零装置用于标准纸箱。打印一到两张测试纸后,机器可调整到正确位置,减少纸板浪费。.

◆ 线间隙调节采用自锁装置,调节范围为 0-12mm。.

◆ 开槽刀头高度和横向调节具有防碰撞保护功能。.

开槽刀宽 7 毫米,由热处理合金制成。齿形开槽刀和双刃修边刀可提供锋利的刃口。.