- 采用多个进口伺服送纸机构,送纸快速、稳定、准确。.

- 无吸无压送纸技术有效保护纸板强度。.

- 强大的吸尘装置可有效清除纸板表面的纸屑。.

- 气动侧挡板,前挡板和左右挡板可电动调节。.

计算机化下单

操作简便

高效率

节省劳动力

透明印刷

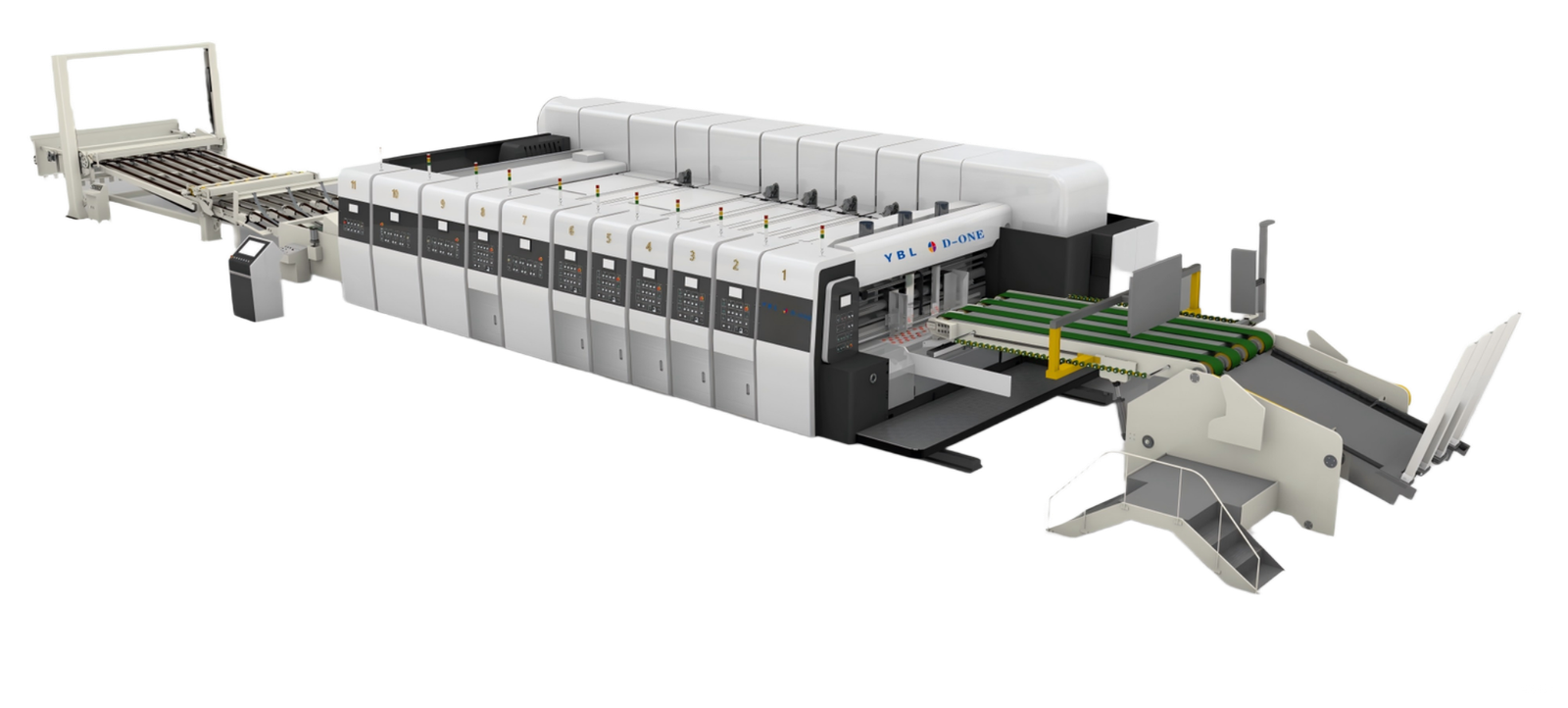

全真空吸附伺服无压自动印刷模切机

我们自主研发的伺服无压送纸系统采用台湾技术,具有四轴前沿送纸功能。这样既能确保准确送纸,又不会破坏纸板的强度。该系统更加稳定耐用,可确保机器长期运行并提高印刷质量。.

多功能、高精度

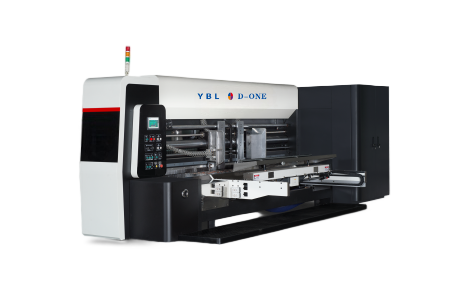

完全无压进纸装置

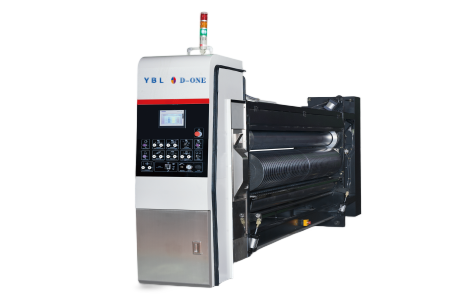

印刷单元

- 打印相位伺服调整,可通过主控计算机或设备的人机界面进行控制。.

- 导纸辊带有快速自锁移动装置和计算机调整间隙。.

- 专门设计的供墨系统可实现高速运行而不飞墨,不粘墨结构,低墨自动报警。.

大型开槽压痕装置

- 多个进口伺服送纸机构确保快速、稳定、准确地送纸。.

- 气吸和无压送纸技术有效确保纸板强度不受损害。.

- 强大的空气吸力和除尘装置可有效清除纸板表面的纸屑。.

- 气动侧挡板、前挡板和左右挡板均可电动调节。.

模切单元

- 模切阶段由主控计算机和设备的人机界面进行调整。.

- 采用进口快换胶垫和胶垫研磨校正机构。进口伺服独立驱动模切胶辊的有效补偿范围为 ± ± ± ± ± ±。

- 上下连杆采用四个螺钉和线性导轨,可实现快速、稳定和精确的尺寸调整。.

- 橡胶辊可自动调整至水平 ±20 毫米,延长了橡胶垫的使用寿命。.

机器功能

送纸单元的前缘辊送纸系统采用全套台湾技术,具有四轴前缘送纸功能,送纸更准确、稳定、耐用,确保机器长期运行。.

1

送纸装置采用进口伺服无压结构,确保了纸板的强度。.

2

双排毛刷和风扇可清除纸板印刷表面的纸屑,提高印刷质量。.

3

前缘部分采用多个独立的伺服送纸系统,确保稳定、准确地送纸。.

4

吸入式波纹管系统取代了橡胶辊送纸系统,可防止纸板被橡胶混合物压碎,破坏纸板强度。.

5

送纸装置的后部采用了三轴抽吸输送系统,并配有两级风门控制,以尽量减少对纸板强度的破坏。.

6

双同步带真空吸附输送系统和线性导轨确保了精确的色彩套准和卓越的打印质量。.

7

灵活的角刀结构便于操作,无需对 3-5 层纸板进行调整。9.压轮的动力传动采用凸轮轴承传动,减少磨损,传动更稳定。.

8

技术参数

| 参数/模型 | YBL-VA-0618 | YBL-VA-0920 | YBL-VA-1224 | YBL-VA-1628 |

|---|---|---|---|---|

| 最大设计速度(件/分钟) | 400 | 转子进给:350 | 250 | 200 |

| 伺服送料:430 | ||||

| 最大纸张尺寸(长 x 宽)(毫米) | 600*1800 | 850*2100 | 1150*2500 | 1550*2900 |

| 最大纸张尺寸(长 x 宽)(毫米) | 900*1900 | 1200*2100 | 1400*2500 | 1800*2900 |

| 最小纸张尺寸(长 x 宽)(毫米) | 210*600 | 300*600 | 350*600 | 400*600 |

| 最大打印尺寸(长 x 宽)(毫米) | 580*1800 | 880*200 | 1150*2400 | 1550*2800 |

| 标准印版厚度(毫米) | 7.2 | 7.2 | 7.2 | 7.2 |

| 最大开槽深度(毫米) | 200 | 450 | 300 | 400 |

| (可提供额外刀片) | (可提供额外刀片) | (可提供额外刀片) | (可提供额外刀片) | |

| 最小开槽间隔 - 前刀片(毫米) | 130*130*130*130 | 150*150*150*150 | 150*150*150*150 | 150*150*150*150 |

| 最小开槽间隔 - 后刀片(毫米) | 210*75*210*75 | 250*70*250*70 | 250*70*250*70 | 250*70*250*70 |

| 套准精度(毫米) | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| 适用纸板厚度(毫米) | 2-12 | 2-12 | 2-12 | 2-12 |

| 开槽和模切精度(毫米) | ±1.0 | ±1.0 | ±1.0 | ±1.0 |

| 模切刀片高度(毫米) | 25.4 | 25.4 | 25.4 | 25.4 |