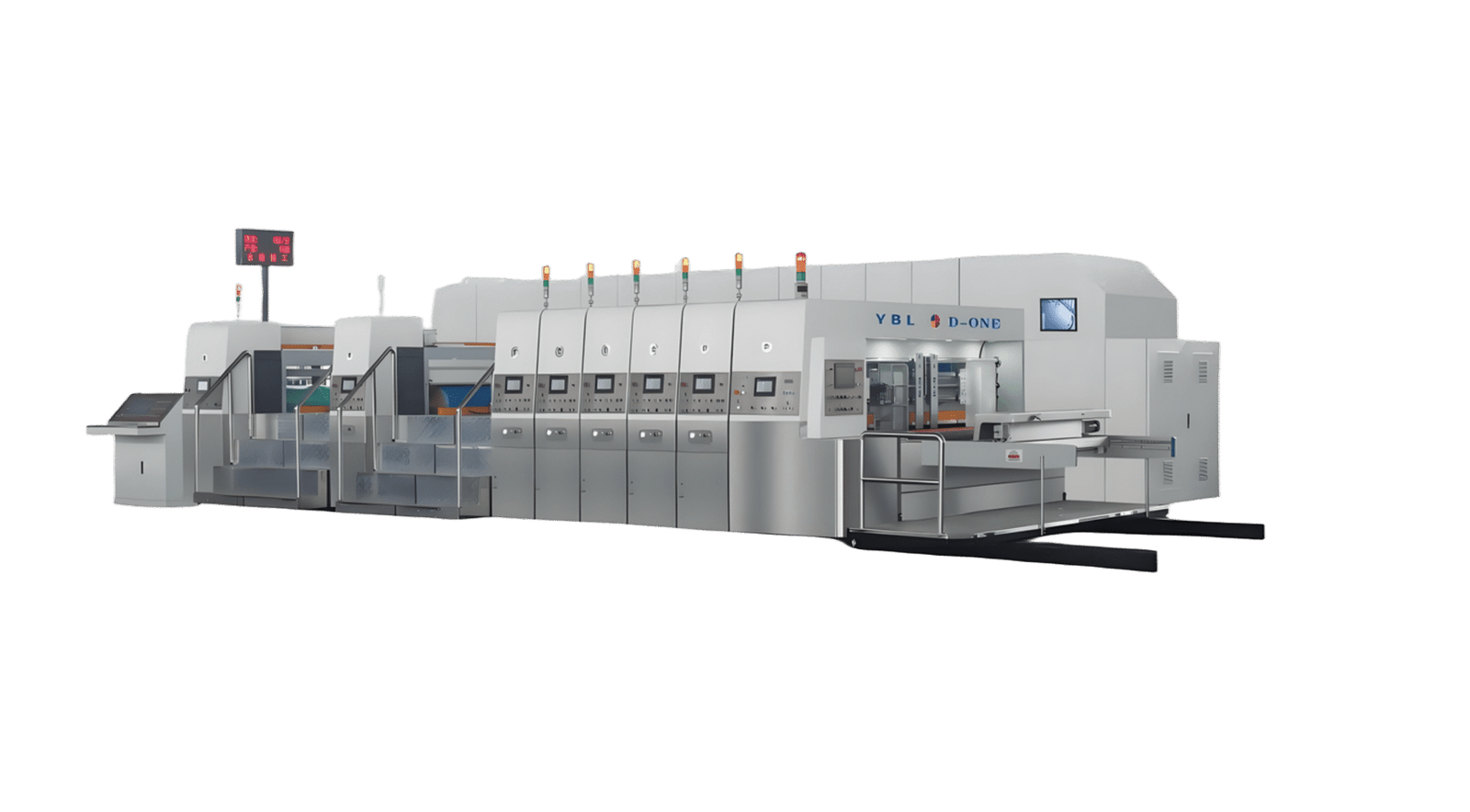

电控机器离合器带有报警铃声,在行驶过程中持续响铃报警,确保操作人员的安全。.

传动轴上装有电磁摩擦离合器,避免误操作损坏机器。停电时可手动打开机组,清理刮板,防止长时间停电造成分格辊堵塞。.

气动联锁装置。.

主机电机启动保护装置,在每个单元关闭后,每组气动锁定,并配备一个总锁定气缸,可使每个单元与底轨锁定融为一体。锁芯未锁定时,主电机无法启动运行;主电机运行时,锁芯无法打开。.

领先的送纸系统,高精度送纸,送纸时间智能控制。可输送硬牛卡纸板和三层、五层、七层纸板。.

真空吸附送纸,克服纸板不同的弯曲度,确保送纸顺畅。.

电动调节侧挡板,手动同步调节前挡板间隙,电动调节后挡板位置。.

可设置计划生产量。计划完成后,系统自动指示停止送纸,并发出警告信号。送纸部分配有 PLC 彩色触摸屏,可显示印刷、上光和模切部分的阶段设置,并可设置和显示生产数量和单次警报。.

配备多通道毛刷、静电除尘,并配有吸尘装置,可清除纸板印刷表面的大量杂质,提高印刷质量。.

高效节能变频电机,真空吸附,全陶瓷吸附送纸轮,送纸顺畅快速。.

送纸部分、印刷部分、上光部分、模切部分电动自动归零。.

一般纸箱采用自动调零装置,试印少的纸张可调整到正确位置,减少纸板浪费。.