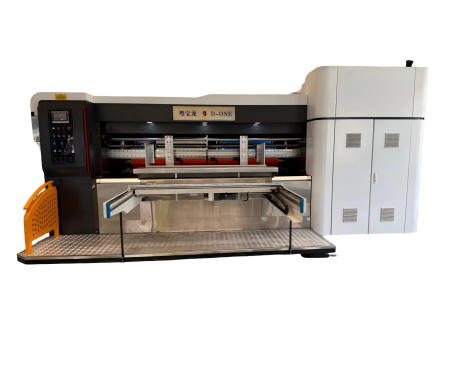

Leading Edge Paper Feeding System

- Vacuum suction paper feeding overcomes variations in cardboard curvature, ensuring smooth paper feeding.

- Pneumatic interlocking device.

- The leading edge paper feeding system offers high-precision paper feeding with intelligently controllable feeding time. It can feed rigid cardboard and three, five, and seven-layer cardboard.

- Left and right side baffles are motor-controlled for left and right movement, with cardboard alignment function.

- Rear cardboard support frame is motor-controlled for forward and backward movement.

- The gap between the front baffles can be manually adjusted synchronously.

- Includes continuous and intermittent paper feeding functions (selectable as needed).

- Utilizes a high-efficiency, energy-saving variable frequency motor for paper feeding, vacuum suction, and all-ceramic suction paper feeding rollers for smooth and fast paper feeding.