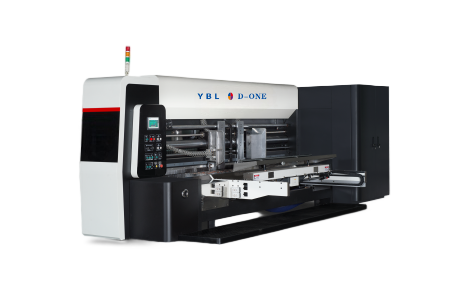

- Employs multiple imported servo paper feeding mechanisms for fast, stable, and accurate paper feeding.

- Suction-free pressure-free paper feeding technology effectively protects the cardboard's strength.

- Powerful suction dust removal device effectively removes paper debris from the cardboard surface.

- Pneumatic side flaps, with electrically adjustable front and left and right baffles.

Computerized Order Placement

Easy to Operate

High Efficiency

Labor Saving

Clear Printing

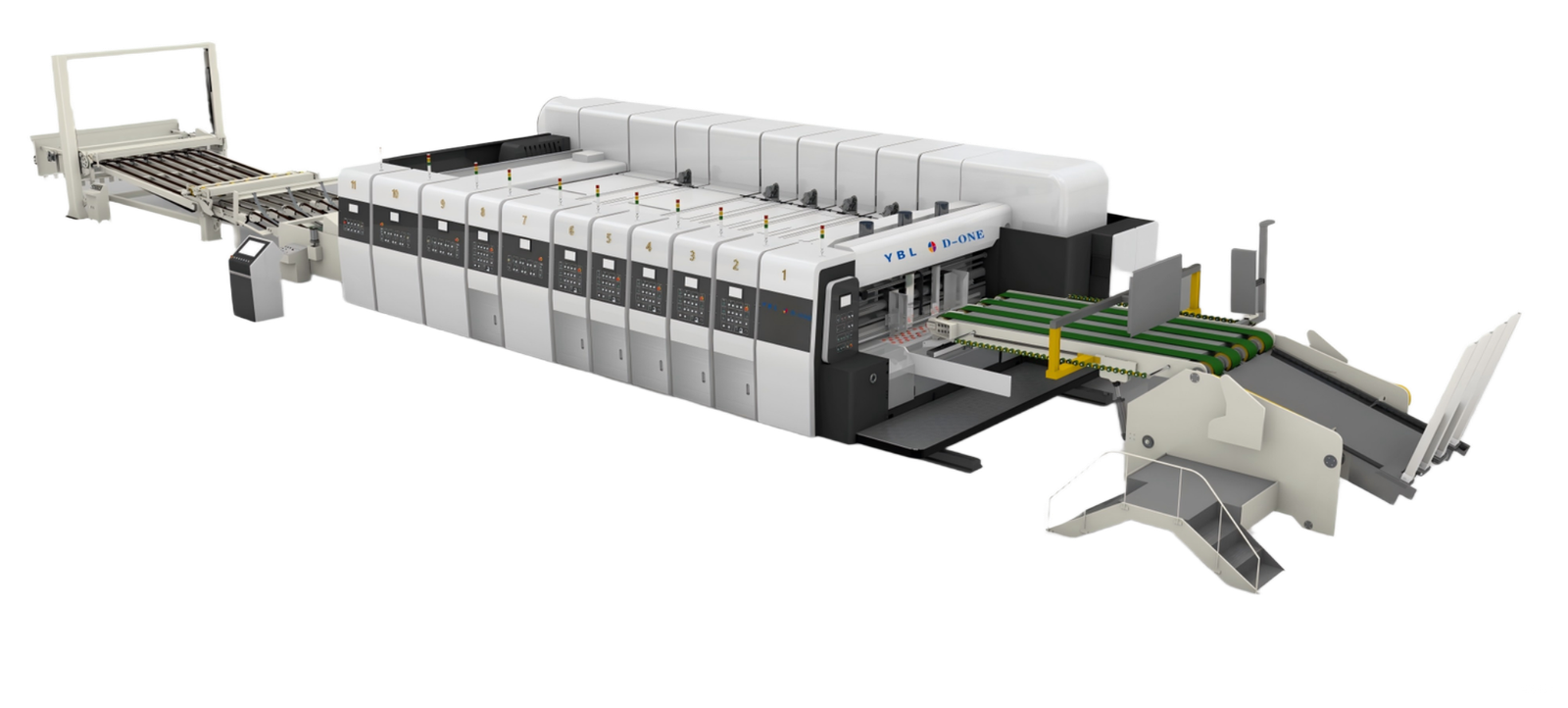

Full Vacuum Absorption Servo Pressure-free Automatic Printing Die-cutting Machine

Our independently developed servo-based pressure-free paper feeding system utilizes Taiwanese technology, with four-axis leading-edge paper feeding. This ensures accurate paper feeding without damaging the cardboard's strength. This system is more stable and durable, ensuring long-term machine operation and improving print quality.

Multi Functions, High Precision

Fully Pressure-free Paper Feeding Unit

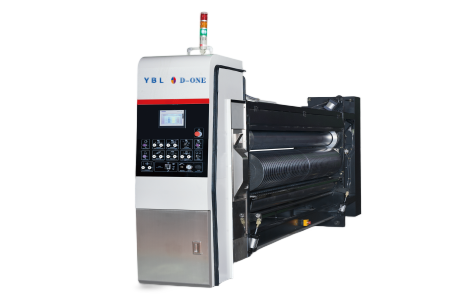

Printing Unit

- Printing phase servo adjustment, controllable by the main control computer or the unit's human-machine interface.

- Paper guide roller with rapid self-locking traverse mechanism and computer-adjusted gap.

- Specially designed ink supply system for high-speed operation without ink flying, non-sticky ink structure, and automatic low-ink alarm.

Large Slotting and Creasing Unit

- Multiple imported servo paper feed mechanisms ensure fast, stable, and accurate paper feeding.

- Air suction and pressure-free paper feeding technology effectively ensures the strength of the cardboard is not damaged.

- Powerful air suction and dust removal device effectively removes paper debris from the cardboard surface.

- Pneumatic side flaps, front and left and right baffles are electrically adjustable.

Die-cutting Unit

- The die-cutting phase is adjusted by the main control computer and the unit's human-machine interface.

- Imported quick-change rubber pads and a rubber pad grinding correction mechanism are used. The imported servo-driven, independently driven die-cutting rubber rollers offer an effective compensation range of ±

- Four screws and linear guides are used for the upper and lower linkages, enabling fast, stable, and accurate dimensional adjustment.

- The rubber rollers automatically adjust to ±20mm horizontally, extending the life of the rubber pads.

Machine Features

The paper feed unit's leading-edge roller feeding system utilizes a complete set of Taiwanese technology, featuring four-axis leading-edge feeding for more accurate, stable, and durable paper feeding, ensuring the machine's long-term operation.

The paper feed unit utilizes an imported servo pressure-free structure, ensuring the strength of the paperboard.

A double row of brushes and a fan remove paper debris from the printed surface of the paperboard, improving print quality.

The leading-edge section utilizes multiple independent servo systems for paper feeding, ensuring stable and accurate paper feeding.

A suction bellows system replaces the rubber roller feeding system, preventing the paperboard from being crushed by the rubber mixture and damaging its strength.

The rear section of the paper feed utilizes a three-axis suction conveyor system with two-stage damper control to minimize damage to the paperboard's strength.

A dual synchronous belt vacuum suction conveyor system and linear guides ensure accurate color registration and superior print quality.

The flexible corner knife structure allows for easy operation, eliminating the need for adjustment for 3-5 layers of paperboard. 9. The power transmission of the pressure wheel adopts cam bearing transmission, which reduces wear and makes the transmission more stable.

Technical Parameters

| Parameters/Models | YBL-VA-0618 | YBL-VA-0920 | YBL-VA-1224 | YBL-VA-1628 |

|---|---|---|---|---|

| Maximum Design Speed(pcs/min) | 400 | Rotor Feed:350 | 250 | 200 |

| Servo Feed:430 | ||||

| Maximum Sheet Size(L x W)(mm) | 600*1800 | 850*2100 | 1150*2500 | 1550*2900 |

| Maximum Sheet Size(L x W)(mm) | 900*1900 | 1200*2100 | 1400*2500 | 1800*2900 |

| Minimum Sheet Size(L x W)(mm) | 210*600 | 300*600 | 350*600 | 400*600 |

| Maximum Printing Size(L x W)(mm) | 580*1800 | 880*200 | 1150*2400 | 1550*2800 |

| Standard Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 | 7.2 |

| Maximum Slotting Depth(mm) | 200 | 450 | 300 | 400 |

| (Additional Blades Available) | (Additional Blades Available) | (Additional Blades Available) | (Additional Blades Available) | |

| Minimum Slotting Interval - Front Blade(mm) | 130*130*130*130 | 150*150*150*150 | 150*150*150*150 | 150*150*150*150 |

| Minimum Slotting Interval - Back Blade(mm) | 210*75*210*75 | 250*70*250*70 | 250*70*250*70 | 250*70*250*70 |

| Register Accuracy(mm) | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| Suitable Cardboard Thickness(mm) | 2-12 | 2-12 | 2-12 | 2-12 |

| Slotting and Die-cutting Accuracy(mm) | ±1.0 | ±1.0 | ±1.0 | ±1.0 |

| Die-cutting Blade Height(mm) | 25.4 | 25.4 | 25.4 | 25.4 |