- 360E design speed: 200m/min;320E design speed: 180m/min

- Effective width: 1400mm- 2200mm.

- Corrugated roller diameter: φ360mm φ320mm

- Adopt negative pressure type design, so that the core paper can be uniformly pressed and attached to corrugated surface, evenly coated with glue to make the single corrugated corrugated paper better.

- Fast change roller, 10 minutes, replace the corrugated roller with electric trolley, into the machine, fixed on the machine base, quick and easy to replace the corrugated roll.

- Corrugated roller and wall-e roller are adopted with high stability air bag control system.

- The control of glue volume control adopts electric adjustment, the rubber device is electric, and the gluing system can operate independently when the host stops, preventing the glue from drying up.

- The portable gluing system is more convenient for maintenance and maintenance than cleaning.

- Simple operation control system, touch screen operation interface, display operation state with color drawing, easy to operate.

- Built-in preset with spray system to adjust core paper temperature and moisture.

Easy to Operate

Computerized Order Placement

High Efficiency

Premium Raw Materials

Labor Saving

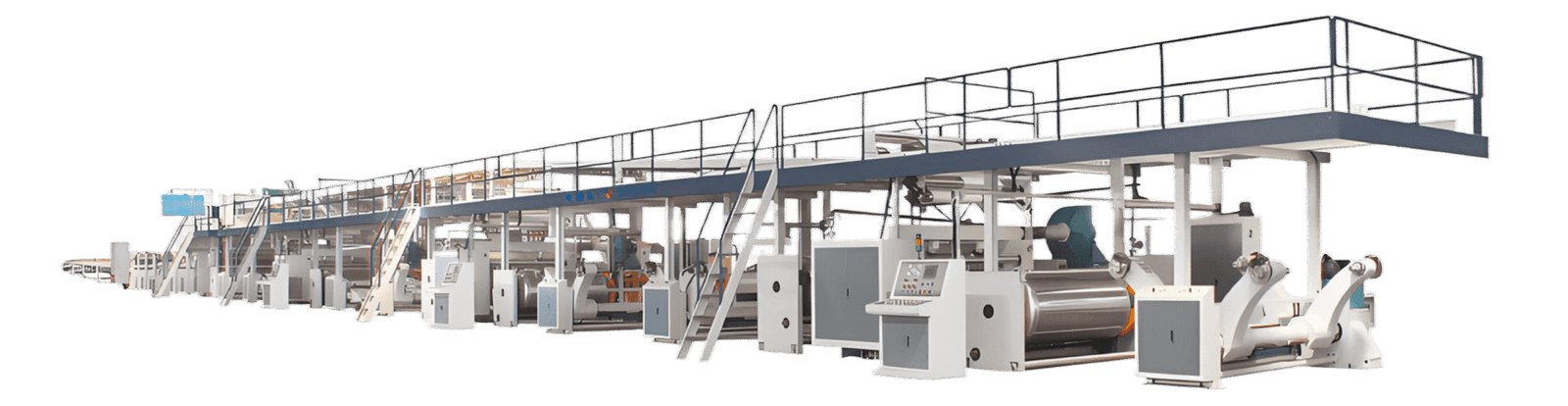

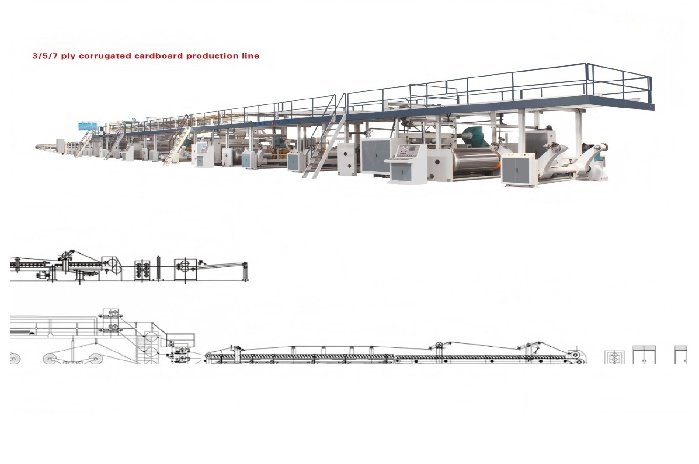

3/5/7 Plyer Corrugated Board Production Line Carton Packaging Machinery

This five-layer corrugated cardboard production line is suitable for large-scale automated production. It produces cardboard that meets national standards, boasts high efficiency and high quality.

Multi Functions, High Precision

SF-360E Drawer-Type Single Facer Corrugator

SF-320C Vacuum Suction-Type Single Facer Corrugator

Features:

- Design speed of SF320C: 150m/min SF360C design speed: 200m/min

- Effective width: 1400mm-2200mm

- Corrugated roller diameter: φ320mm φ 360mm

- Drive the gearbox to lubricate the oil, reduce the noise, the universal joint drive, and isolate the power source (optional).

- Upper roller, pressure roller and rubber roller lift, all with pneumatic control.

- The guide paper adopts vacuum adsorption, with air volume adjustment device, to maintain the

- stability of corrugated and corrugated form at high speed.

- The roller and pressure roller bearings are lubricated with high temperature resistance grease.

- The glue is used for adhesive.

- The upper and lower corrugated roller adopts 48CrMo high quality alloy steel, after heat treatment, hardness is above HV1200, surface carbonized tungsten or hard chromium plating treatment.

- The surface of the rubber roller is treated with the mesh cut and chrome plating.

- Manual or electric separation device.

- The glue department can be operated independently or independently in two ways.z

SF-280SVacuum Suction-Type Single Facer Corrugator

- Designspeed: 100m/min.

- Effectivewidth: 1200mm- 1800mm.

- Corrugatedroller: φ

- Thedriving reducer adopts oil penetration lubrication, reducing noise, universal joint drive and isolating power

- Upperroller, pressure roller and rubber roller lift, all with pneumatic

- 6The guide paper adopts vacuum adsorption, withair volume adjustment device, to maintain the stability of corrugated type in high speed.

- Theroller and pressure roller bearings are lubricated with high temperature resistance

- Thegelatinize part adopts automatic circulation for glu

- The upper and lower corrugated roller adopts 48CrMo high quality chromium aluminum alloy steel, after heat treatment, thehardness is grinding on the surface of hrc58o-

- Thesurface of the rubber roller has been treated with the mesh cut and chrome

- Manualor electric separation devic

- Themachine can operate independently or without independent operation, and the main power converter control (optional).

.png)

ZJ-V5B Hydraulic Shaftless Mill Roll Stand

- The double-roller, symmetrical four-arm structure can support two rolls of base paper simultaneously.

- Hydraulic transmission enables clamping, lifting, and deflection correction of the paper rolls.

- A multi-point brake or manual tension brake is used at the tail end of the top, and the top uses a toothed chuck to reduce paper waste.

- Base paper widths range from 1200mm to 2500mm, and the supported base paper diameter is 1500mm.

- Maximum weight: V5B: 2.5 tons, V6B: 3.5 tons.

- Spindle diameter: φ242mm/φ270mm

ZJ-F Electric Shaftless Mill Roll Stand

- Base paper diameter 1400mm

- Maximum weight 2 tons

- Single-slide, symmetrical four-arm structure capable of supporting two rolls of base paper simultaneously

- Pneumatic single-point brake

- The arm clamping and rotation mechanisms are equipped with a constant torque clutch for safe and reliable operation.

MH-1100T Multi-Roll Corrugator Preheater

- Preheating roller diameter: φ600mm, φ900mm, φ1000mm, or φ1100mm.

- Effective width: 1400mm-2500mm

- Motorized wrap angle adjustment, 360° rotation, and optional two wrap angle shafts for increased wrap angle area.

- Each roller surface is precision-ground and hard-chrome-plated for a smooth, durable finish.

- A dished head design ensures uniform heating of the base paper.

- Available in single or multi-layer configurations.

GM-E Heavy-Duty Double-Layer Gluing Machine

- Design speed 250 m/min, sizing roller diameter 320 mm.

- Each layer of gluing rollers is independently controlled by a variable frequency motor. This inverter control ensures synchronized linear speeds for each layer while also enabling independent operation.

- Because each layer of gluing rollers is independently controlled by a variable frequency motor, the inverter can still be used to synchronize the linear speeds of each layer even after sizing roller refurbishment.

- Glue application and control are available in both manual and automatic modes.

- Manually, the motor is jogged according to the speed to achieve the desired gluing control.

- Automatically, the encoder and PLC automatically control the gluing control based on speed changes, with the value displayed on the human-machine interface. This ensures the desired gluing amount at both high and low speeds, ensuring consistent corrugated paper quality.

- When the machine is shut down, the contact roller automatically raises, and the gluing rollers (gluing rollers) automatically idle.

- Available pressure roller or elastic contact bar pressure modes.

SM-E Double Facer

- Design speed: 200-250m/min, width 1800mm-2500mm

- PLC-controlled human-machine interface automatically switches the number of heating plates and pressure level to ensure the flutes remain intact for various corrugated paper weights.

- The heating plates are surface-treated and hard-chrome plated. Width 600mm. Available in 18-22 plates.

- The hot section utilizes a hot press plate structure with pneumatic pressure adjustment in sections (optional) to adjust the thickness of the paperboard being produced.

- The upper cotton webbing utilizes a dual-cylinder S-shaped tensioning device. Manual or automatic webbing feed and deflection correction are available.

- The drive unit utilizes an independent gearbox and is driven by either an electromagnetic speed-controlled motor or a variable-frequency motor.

- The drive roller is covered with wear-resistant rubber and features a herringbone-shaped structure with a mid-height belt to ensure smooth paperboard delivery.

NCBD Computerized Thin Blade Slitter Scorer

Features:

- Mechanical speed: 250m/min. Effective width: 1400mm-2500mm

- Capable of storing 999 sets of orders, enabling automatic or manual order changes without stopping the machine.

- Optional servo control of the slitting blade and creasing rollers ensures fast and accurate order placement.

- Two rows of creasing rollers are configured, front and rear, allowing any combination of creasing rollers to achieve zero creasing.

- Automatically tracks production line speed to ensure synchronization, and can be connected to production management systems for strong compatibility.

- Upper and lower computer control systems comprise a high-quality imported industrial computer and a high-performance programmable controller.

- Three creasing types are available: convex-concave (three-layer), convex-concave (five-layer), and convex-flat, with electric switching. The creasing roller depth is automatically controlled by the computer, ensuring a smooth line shape and easy bending.

- Uses thin tungsten alloy blades with a sharp edge and a service life exceeding 8 million meters. 9. The knife can be sharpened automatically or manually under computer control, allowing simultaneous sharpening during slitting, improving production efficiency.

- It utilizes an imported synchronous drive mechanism, ensuring high precision, long life, and low operating noise.

- A waste suction port is standard, and the left and right waste suction ports adjust synchronously with the knife during order changes.

ZQS Motorized Thin Blade Slitter Scorer

- Design speed: 150m/min

- Effective width: 1400mm-2200mm

- Cutter wheel configurations: Four-blade six-line, five-blade eight-line, six-blade ten-line.

- Utilizes novel thin blades for high-speed paper cutting, resulting in smooth and even cuts.

- Automatic blade sharpening system allows for continuous sharpening during production. The pneumatically controlled sharpening mechanism allows for adjustable intervals and sharpening time based on the material and weaving conditions.

- Integrated electric traverse effectively adjusts to paperboard deviation.

NC-120 Computerized Helical Knife Cross-Cutter

- Design speed: 100-150m/min; effective width: 1400-2200mm

- 200 sets of orders can be stored, allowing for quick and accurate changes in paper cutting specifications without stopping the machine. Computer networking is also available for convenient production management.

- The drive gears on the cutter shaft are made of precision-forged steel and high-frequency quenched, achieving zero backlash transmission. Advanced seamless connection technology ensures high transmission accuracy.

- The cross-cutting blades utilize a serrated steel spiral blade structure. This scissor-like shearing method provides low shear force and long blade life.

- Both the front and rear paper feed rollers utilize a sun gear pressure mechanism, ensuring smooth paper feed and uniform pressure, preventing damage to the paper sheets or jams.

- This machine utilizes energy storage braking (non-energy-consuming braking), resulting in low energy consumption during production. Average power consumption is one-third that of conventional NC cutters, saving over 70% and achieving cost savings.

- Precision, adjustable, zero-backlash gears ensure precise blade engagement and balanced operation. 8. An independent oil pump and filter, along with two sets of copper pipes, are used to supply oil to each gear position for lubrication and cooling.

- Cutter Roller: Made of high-quality precision-forged steel and balanced for optimal balance.

DHD-150 Computerized Single Facer Slitter and Cross-Cutter

- Effective Width: 1600-2200mm

- Maximum Speed: 150m/min

- Number of Slitting Blades: 5

- Minimum Slitting Width: 180mm

- Arrangement Time: 3-8s

- Arrangement Accuracy: 0.5mm

- Cross-cut Length: 300-9999mm

- Cross-cut Accuracy: 1mm (Constant Speed)

- Stacking Height: 250-600mm (Customer Requirement)

- Maximum Cardboard Stacking Length: 1600mm

- Constant Tension Cardboard Conveyor, Conveyor Speed Strictly Synchronized with Single-Fader Speed.

- Thin Alloy Steel Slitting Blades with Automatic Sharpening for Long Blade Life and High Slitting Quality.

- Independent Servo Control for Slitting Blade Arrangement, Fast, Accurate, and Reliable.

- Slitting Speed Controlled by a Variable Frequency Motor and Inverter, Adjusts Synchronously with Cardboard Speed. 15. The left and right scrap suction ports are electrically adjusted to follow the edge cutter during job changes.

- The cross-cutting section housing is constructed of high-quality castings, undergoes rigorous aging treatment, and undergoes precision machining, ensuring long-term, stable operation.

- The spiral cutter shaft is constructed of seamless alloy steel pipe, economically machined and dynamically balanced, resulting in high rigidity and low inertia.

- The cross-cutting cutter utilizes a German Kobe AC servo controller.

DMT-120 Right-Angle Stacker

- Working Width: 1400mm-2200mm

- Operating Speed: 100m/min-180m/min

- Maximum Sheet Length: 3000mm-3500mm

- Automatically stacks and collects cardboard sheets.

- Powered lateral output, with electrically adjustable rear stop.

- Longitudinal splices are transported using a wide conveyor belt.

- When the required number of sheets or height is reached, the sheet can be automatically or manually removed.

DMC-200 Fully Automatic Gantry-Style Stacking Machine

- Effective width: 1400mm-2500mm, design speed: 200m/min-250m/min

- Maximum stacking height: 250mm, maximum stacking length: 3500mm

- Gantry stacking. Order change time is 5 seconds, with automatic counting, automatic horizontal ejection, and automatic order change.

- Synchronized with the production control system for centralized order management and automatic order change without speed reduction.

- Production control order change waste is less than 700mm

- Crawler-type stacking platform, AC servo-controlled lifting and lowering, ensuring smooth and orderly stacking.

- Frequency conversion control automatically and smoothly ejects paper horizontally when the set stacking quantity is reached.

- AC servo-controlled positioning of the rear stop allows for automatic, fast, and precise adjustment during order change.

- Automatic rear stop shifting makes it suitable for stacking small orders.

- The conveyor side is equipped with a standard electric conveyor frame and a dual-station trolley.

- Independent sealed control cabinet ensures electrical equipment operates in a dust-free environment.

- Color touchscreen display facilitates on-site operation.

- Fully automatic operation control improves efficiency, saves manpower, and reduces operator workload.

Fully Automatic Paper Splicer

- Design speed: 150m/min

- Maximum applicable base paper diameter: 1500mm

- Combined with the base paper holder's automatic tension control, it enables high-speed splicing and high efficiency.

- No-tail splicing reduces base paper loss (the overlapped portion of the base paper is only approximately 40mm wider than the tape).

- The splicing cart automatically rotates out when it moves out, and uses vacuum suction for easy paper loading. Fully automatic tension control ensures error-free splicing.

- Fully PLC-controlled operation ensures accurate operation, minimal malfunctions, and easy maintenance.

- The buffer wheel automatically aligns the paper during the first pull, ensuring easy paper pulling.

NC-1800 CNC Single-Knife Paper Cutter

General Technical Parameters:

- Working Width: 1800mm

- Machine Speed: 60m/min

- Minimum Cutting Length: 300mm

- Maximum Cutting Length: 9000mm

- Cutting Accuracy: ±1.5mm at a Constant Speed

Power Motor and Electrical Parameters:

- Main drive motor power: 3 kW

- Fully AC synchronous servo control

- Papermaking motor power: 3 kW (variable frequency)

Machine Features

This five-layer corrugated cardboard production line is suitable for large-scale automated production. It produces cardboard that meets national standards, boasts high efficiency and high quality.

Centralized control ensures easy operation, convenient maintenance, and a safe, reliable system, significantly reducing worker workload.

This line utilizes the latest international energy-saving technology, using high-temperature thermal oil to heat the entire machine. This saves over 40% of energy compared to other heating methods, significantly reducing energy consumption and effectively reducing production costs. It is an ideal, economical product suitable for medium and large carton factories.

The total length of the entire machine is 50-100 meters.

The total power of the entire machine is approximately 100-200 kW.

Two types of mechanical and hydraulic supports are available.

Laminating Machine: The corrugating rollers have a diameter of 280mm-405mm and utilize electromagnetic speed control motors.

Secondary Gluing Machine: Easy adjustment and uniform glue application.

Dryer: The total length is 7.8 meters and consists of 9-18 heating plates.

Forming Section: Consists of several pairs of forming shafts, with a total length of approximately 3.8-5 meters.

Longitudinal and Horizontal Slitter: Available with either an ultra-thin blade or a standard blade, depending on user requirements. These machines feature a high degree of automation and are easy to operate.