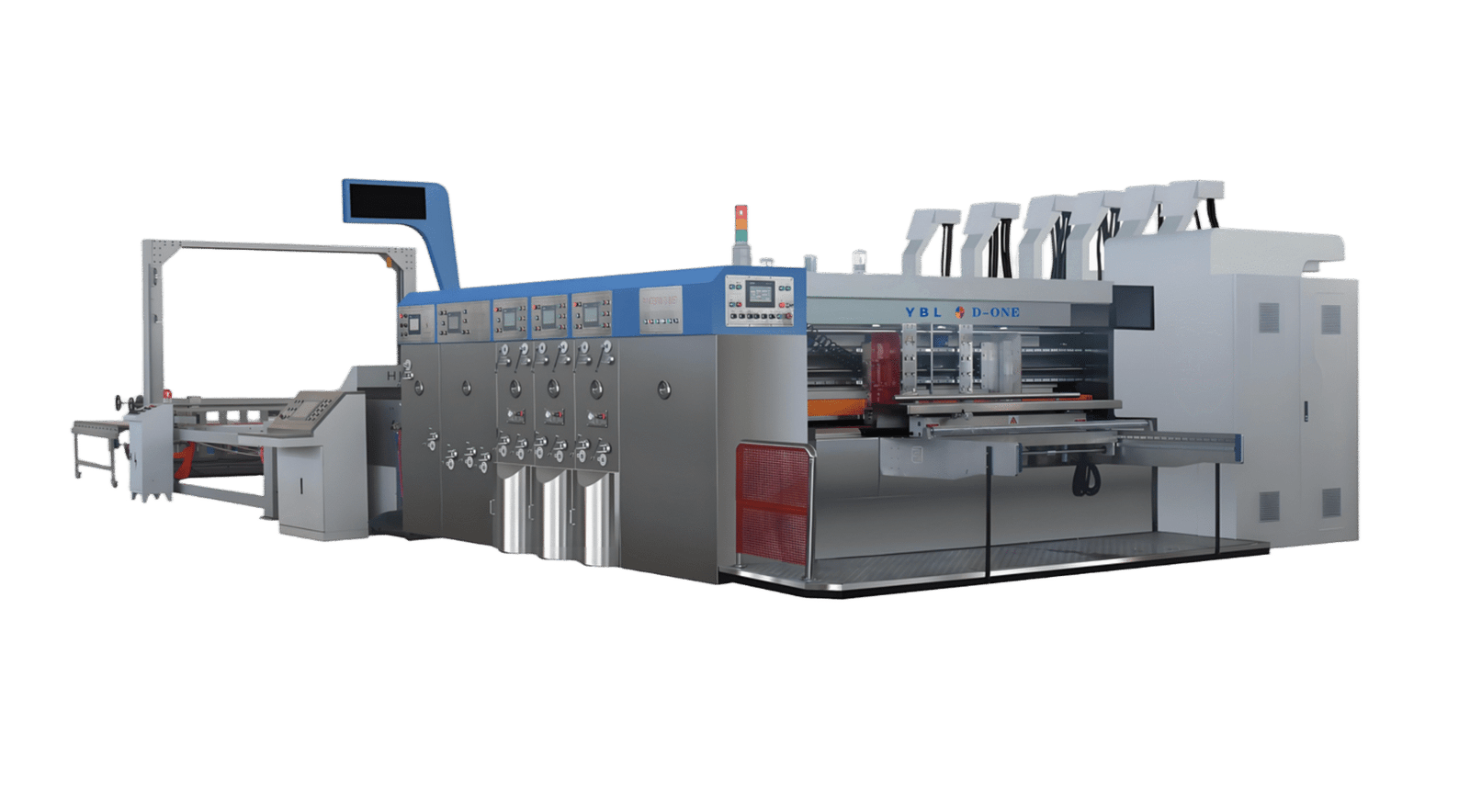

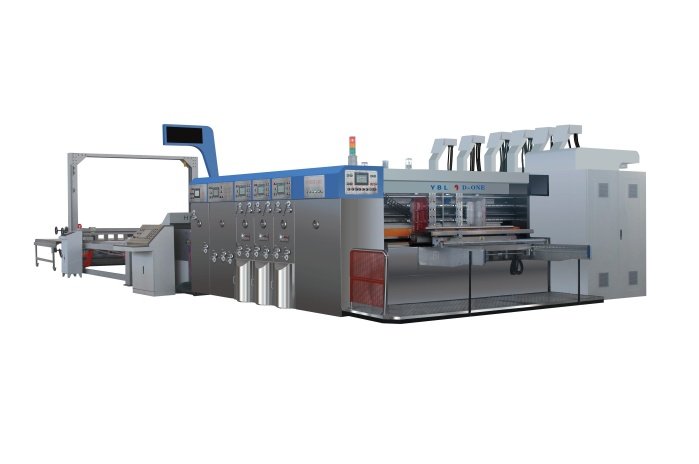

◆ Roller-type leading-edge paper feed mechanism, multi-wheel, multi-point suction feeding, provides high friction, high speed, and smooth, accurate paper feeding.

◆ Suction air volume is adjusted by frequency conversion, and air pressure can be adjusted according to cardboard size, enhancing transmission stability and accuracy for thin and warped cardboard.

◆ Dual-roller feed structure: One set of feed rollers utilizes a pneumatic elastic feed roller, which does not damage the strength of the corrugated cardboard. A cleaning brush removes surface debris, while a high-pressure fan removes impurities from the cardboard surface, improving print quality.

◆ The left and right baffles and rear baffle are electrically adjustable, while the front baffle gap is manually adjusted. The side baffles are equipped with a pneumatic alignment device for more accurate horizontal cardboard positioning. ◆ A 10.4-inch color touchscreen controls the paper feed, printing, slotting, and die-cutting sections, with one-time reset, order storage, memory positioning, cruise control at 60, 80, 100, and 120 mph, infrared photoelectric counting, and preset order quantities.

◆ The main machine utilizes variable frequency control for smooth startup and operation, saving 30% energy.